Which Motor is Best for a CNC Machine?

Choosing the right motor for your CNC machine is crucial for optimizing performance, precision, and efficiency. The motor serves as the heart of the CNC system, driving the machine’s movements and enabling it to perform various tasks like cutting, milling, engraving, and drilling.

In this comprehensive guide, we will break down the different types of motors used in CNC machines, their advantages and limitations, and how to select the best one for your business’s specific needs. Whether you're a manufacturer, wholesaler, or CNC machine user, understanding the motor options available is key to making the right decision for your operations.

Table of Contents

Introduction to CNC Motors

Types of Motors Used in CNC Machines

Factors to Consider When Choosing the Best Motor for Your CNC Machine

Stepper Motors vs Servo Motors : Which is Better for Your CNC Machine?

How to Choose the Best Motor for Your CNC Machine

Key Advice for Wholesalers and B2B Customers

Conclusion: Finding the Right Motor for Your Business

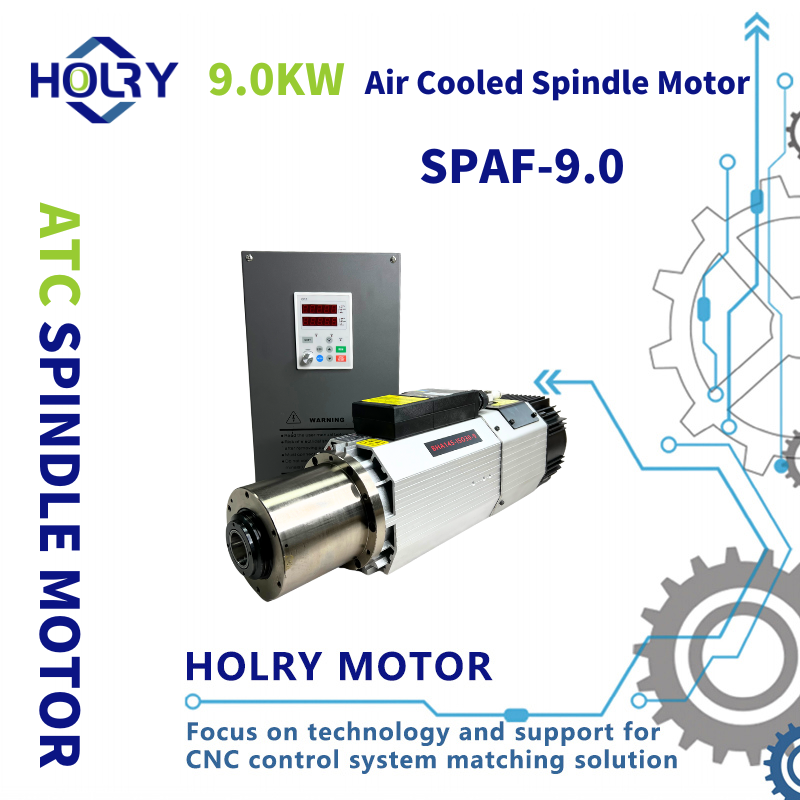

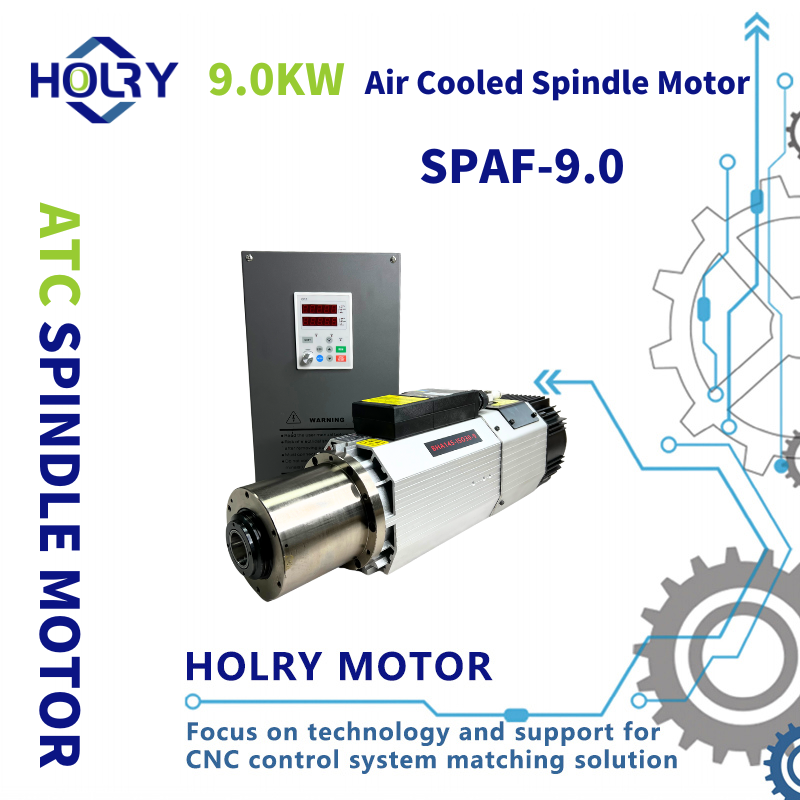

High Speed Air-cooled ATC 9.0kw Spindle Motor ISO30 CNC Spindle for Cnc Router

ATC 13.5kw Spindle Motor HSK63F CNC Spindle

Air-cooled ATC 7.5kw Spindle Motor ISO30 CNC Spindle

1. Introduction to CNC Motors

CNC (Computer Numerical Control) machines are central to modern manufacturing. These machines use motors to convert digital commands into physical movement, making them capable of performing highly precise tasks like cutting, engraving, and milling.

There are several types of motors used in CNC machines, each offering different benefits depending on the application. The primary goal when selecting a motor is to match the machine’s capabilities to the specific tasks it will perform. Factors such as speed, torque, power, and precision play critical roles in the motor selection process.

In this guide, we will explore the most common motor types used in CNC machines, along with their applications and advantages. We will also provide valuable tips for wholesalers and B2B customers on how to select and sell the right motors for different industries.

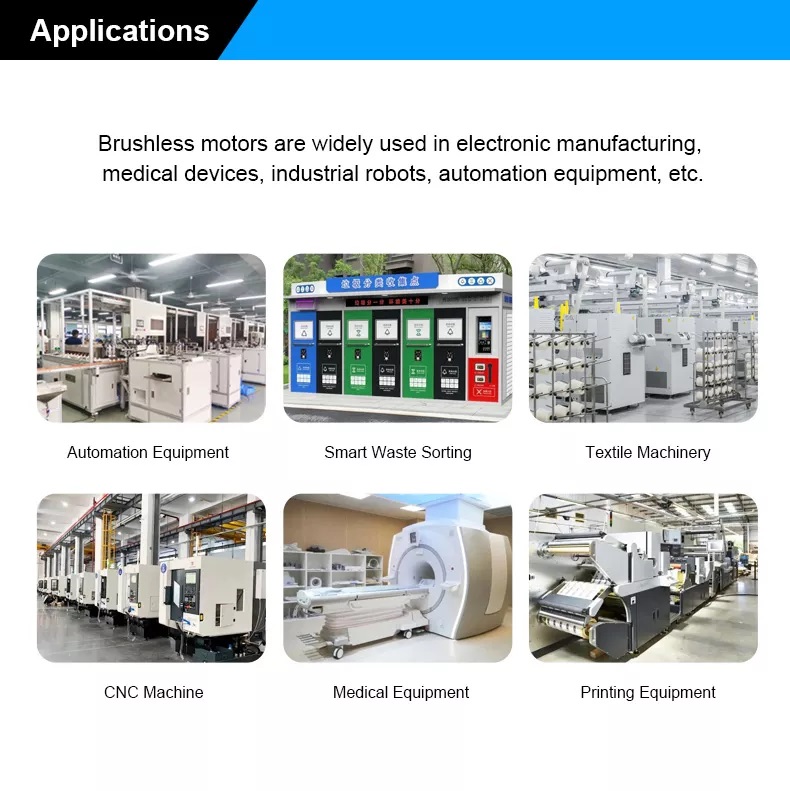

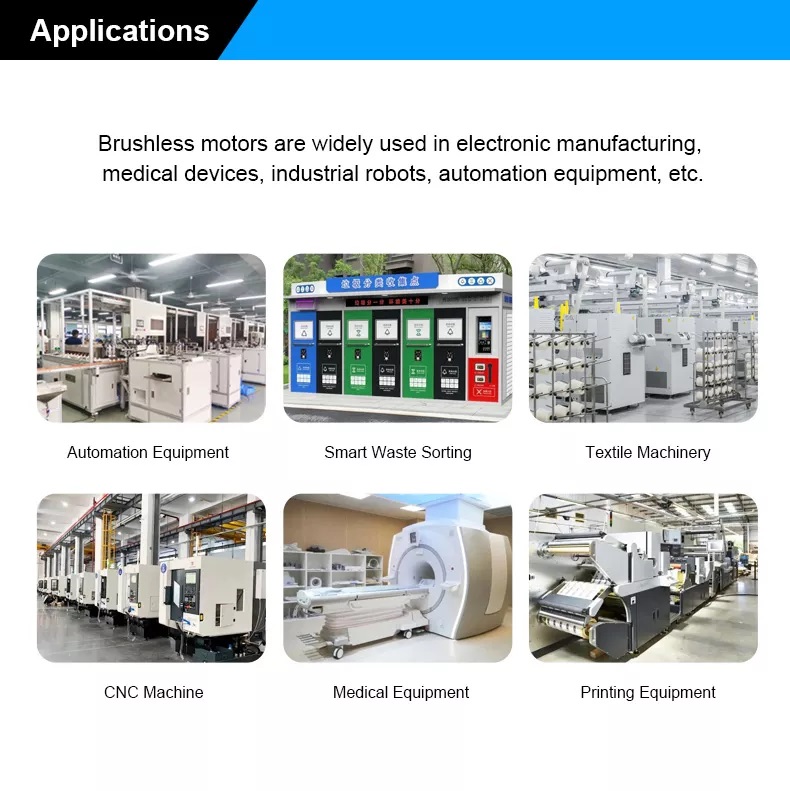

2. Types of Motors Used in CNC Machines

Stepper Motors

Step motors are one of the most common motor types used in CNC machines, especially for light-duty applications. Stepper motors divide each full rotation into a series of discrete steps. These motors are controlled by sending pulses to the motor driver, which results in precise control over the motor's rotation.

Key Features of Stepper Motors:

Precision Control: Stepper motors are ideal for applications that require precise positioning, like engraving, 3D printing, or small part manufacturing.

Open-Loop Control: Stepper motors do not require feedback systems (such as encoders) to operate effectively. This makes them more cost-effective for many applications.

Low Cost: Stepper motors are relatively inexpensive, making them a popular choice for budget-conscious businesses.

Torque at Low Speeds: Stepper motors provide excellent torque at low speeds, making them ideal for light-load operations.

Applications: Stepper motors are commonly used in applications like 3D printing, small milling machines, CNC routers, and laser engraving machines.

Servo Motors

Servo motors are high-performance motors that combine a motor with a feedback system, allowing for continuous monitoring and adjustment of position, speed, and torque. They are typically used in high-precision and high-speed CNC machines, offering superior performance compared to stepper motors.

Key Features of Servo Motors:

High Efficiency: Servo motors are energy-efficient and can provide higher torque at higher speeds than stepper motors.

Closed-Loop Control: The feedback system in servo motors allows them to continuously adjust the motor’s speed and position, resulting in greater accuracy and smoother operation.

High-Speed Performance: Servo motors are ideal for high-speed machining tasks that require both high torque and precise positioning.

Higher Cost: Servo motors are generally more expensive than stepper motors, but the increased performance justifies the price for many applications.

Applications: Servo motors are typically used in CNC machines that require high-speed, high-precision operations, such as in the automotive, aerospace, and medical device industries.

DC Motors

DC motors (Direct Current motors) are commonly used in CNC applications where high starting torque and variable speed control are essential. These motors are powered by direct current and can easily change speed by varying the input voltage.

Key Features of DC Motors:

Variable Speed: DC motors offer easy speed control by adjusting the voltage applied to them, making them ideal for applications that require varying speeds.

Simple Control System: DC motors are relatively simple to control and can be used in systems where complex control is not required.

Good Torque at Low Speeds: DC motors are effective at providing high torque at low speeds, making them ideal for applications that require strong starting torque.

Applications: DC motors are commonly found in low-cost CNC machines, hobbyist machines, and smaller applications where precise control and high speed are not critical.

AC Motors

AC motors (Alternating Current motors) are typically used in industrial CNC applications where high power and reliability are needed. AC motors are more efficient at higher speeds and can handle larger loads, making them ideal for heavy-duty tasks.

Key Features of AC Motors:

High Power: AC motors are powerful and efficient, able to handle high-load applications.

Durability: AC motors are designed for continuous operation, making them ideal for high-demand industrial environments.

Variety of Types: There are two main types of AC motors used in CNC machines: synchronous motors and induction motors. Both types offer excellent speed control and reliability.

Applications: AC motors are ideal for large CNC machines, industrial milling machines, lathes, and high-precision machines used in the aerospace and automotive industries.

3. Factors to Consider When Choosing the Best Motor for Your CNC Machine

Selecting the best motor for your CNC machine is not a one-size-fits-all decision. Several factors influence the motor selection process, and each factor will depend on the type of machining, material being processed, and machine size.

Power Requirements

The power requirement of your CNC machine will determine the type of motor that is best suited for your operations. High-power applications, such as those in heavy-duty industries, will benefit from AC or servo motors, while lighter tasks may be better suited to stepper or DC motors.

Precision and Accuracy

If your CNC machine requires high precision, such as in medical device manufacturing or aerospace applications, a servo motor with feedback control will likely be the best choice. Stepper motors are good for less demanding precision tasks, such as small-scale engraving or 3D printing.

Budget Considerations

While servo motors offer excellent performance, they come at a higher price point than stepper motors. If you’re working with a limited budget, stepper motors may be a good starting point. However, for businesses looking to achieve higher throughput and precision, the investment in a servo motor may be worth the cost.

Speed and Torque

For operations that require high-speed performance, a servo motor is ideal. On the other hand, stepper motors excel at providing consistent torque at lower speeds, which makes them useful for applications like 3D printing and small milling tasks.

Maintenance and Durability

Servo motors require more maintenance due to their complex feedback systems, while stepper motors are simpler and tend to be more durable with fewer parts that wear down over time. If long-term durability and low maintenance are critical for your operations, stepper motors may be the right choice.

4. Stepper Motors vs Servo Motors : Which is Better for Your CNC Machine?

Stepper Motors : Pros and Cons

Pros:

Cost-effective and easy to implement.

Ideal for low to medium-speed applications requiring precise control.

Simple control systems with fewer components to maintain.

Cons:

Best For: Low-cost, entry-level CNC machines and applications that do not require high-speed or high-torque operation.

Servo Motors : Pros and Cons

Pros:

High efficiency, speed, and torque performance.

Closed-loop system with continuous feedback for precise control.

Excellent for high-speed, high-precision operations.

Cons:

Best For: High-performance CNC machines, industrial applications, and tasks that require high-speed and precision.

5. How to Choose the Best Motor for Your CNC Machine

When choosing the best motor for your CNC machine, you should consider your specific operational needs. Follow these steps to make the right decision:

Identify Your Requirements: Determine the types of materials you will be working with, the complexity of tasks, and the desired level of precision.

Assess Your Budget: Evaluate the initial costs and long-term performance of the motors. For heavy-duty and high-performance tasks, consider investing in servo or AC motors.

Consider Power, Speed, and Torque Needs: Understand the power and torque requirements of your CNC machine and choose a motor that aligns with these specifications.

Factor in Maintenance: Consider how much time and effort you are willing to dedicate to maintaining the motor. Stepper motorsare generally simpler to maintain, while servo motors require more attention due to their complex feedback systems.

Consult with Experts: If you're unsure about which motor is best for your specific needs, don't hesitate to consult with an expert or trusted supplier. Companies like Holry offer professional guidance and can help you choose the ideal motor based on your machine's specifications and performance requirements.

6. Key Advice for Wholesalers and B2B Customers

For wholesalers and B2B customers in the CNC machine industry, offering the right motors to your clients can significantly impact their operations. The motor you provide should align with the specific needs of your customers, ensuring that their machines run efficiently and meet performance targets. Below are some tips to help you succeed in supplying the best motors:

A. Understand Your Customer's Application Needs

Different CNC applications require different motor types. For example:

Hobbyists or Small Businesses: Stepper motors are typically sufficient for smaller machines, where high precision and low-speed operations are required. These customers often prioritize budget-friendly options.

Industrial Applications: Larger businesses or those working with heavy-duty materials (e.g., metals, composites) will require motors like servo motors or AC motors for their high speed, torque, and precision needs. Such clients usually prioritize high performance and reliability over cost.

Make sure you understand your customer's specific application, whether it’s for a low-cost, high-precision engraving task or a high-speed, heavy-duty industrial operation. This will help you provide the best recommendation and ensure customer satisfaction.

B. Provide a Range of Motor Options

It’s essential to stock a variety of motors to meet the needs of different customers. Offering a range of motor types (stepper, servo, DC, and AC motors) will allow you to cater to a wide array of industries. Additionally, customers may want to upgrade or switch motors as their business grows, so having different options on hand is important.

C. Offer Custom Solutions

Some industries may require custom motor solutions for specific applications. For example, customers in the aerospace or medical device manufacturing industries often need motors that meet stringent precision and speed standards. As a wholesaler, you can work with motor manufacturers to provide custom motor solutions tailored to the specific needs of your clients.

D. Educate Your Customers

Many businesses may not fully understand the different motor types and their specific applications. As a wholesaler or distributor, it’s your job to educate your customers about the differences between motors and how each type can benefit their CNC operations. Offering educational resources, technical support, and hands-on demonstrations can help build trust and customer loyalty.

E. After-Sales Support

CNC machines and their components, including motors, require ongoing maintenance. Providing after-sales support can set you apart from your competitors. Offering technical assistance, troubleshooting, and warranty services can help you build long-term relationships with your customers.

7. Conclusion: Finding the Right Motor for Your Business

In conclusion, selecting the right motor for your CNC machine is a critical decision that will affect your machine’s performance, precision, and overall efficiency. Whether you’re running a small business or working in large-scale manufacturing, understanding the different motor types—stepper, servo, DC, and AC—and their applications will help you make an informed choice.

Key Takeaways:

Stepper motors are ideal for light-duty tasks and applications that don’t require high speed or torque.

Servo motors offer high efficiency, precision, and performance, making them the best choice for high-demand, industrial-grade operations.

DC motors are a cost-effective solution for low-cost CNC machines requiring variable speed and high starting torque.

AC motors are perfect for heavy-duty applications where high power and continuous operation are required.

When choosing a motor, you should consider factors such as power, speed, torque, precision, and budget. Wholesalers should focus on offering a variety of motors to suit their customers' needs, providing both standard and customized solutions for different industries.

If you’re unsure which motor is best for your application, Holry is here to help. With our wide range of high-quality CNC motors and expert guidance, we can help you choose the right motor for your machine, ensuring improved performance and efficiency for your business.

Call to Action:

Ready to upgrade your CNC operations?

Contact Holry today for expert advice and top-quality CNC motors that suit your needs. Whether you’re a hobbyist, small business owner, or large-scale manufacturer, we can help you find the perfect motor solution for your CNC machines.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

বাংলা

Hrvatski

Eesti keel

latviešu

ગુજરાતી

Igbo

Lietuvių

मराठी

ਪੰਜਾਬੀ

తెలుగు

Yorùbá

isiZulu