Real case analysis and in-depth technical guide

In the current wave of digital transformation in manufacturing, CNC (Computer Numerical Control) milling machines, as the core equipment for precision processing, their efficiency directly determines the competitiveness of enterprises. According to a McKinsey report, the global demand for manufacturing efficiency improvement increased by 25% in 2023. Among them, as the "heart" of CNC systems, the performance optimization of spindle motors has become a key breakthrough point. However, many factories still face the bottlenecks brought by traditional spindle motors: slow response, precision fluctuations and excessive energy consumption. These problems not only lead to production delays but also increase operating costs. HOLRY, a professional manufacturer with 17 years of experience in spindle motor research and development, has helped countless enterprises achieve efficiency leaps with its servo spindle motor series. This article, through a real case of a German precision parts manufacturing enterprise, deeply analyzes how to increase the efficiency of CNC milling machines by 30% by using HOLRY servo spindles, and provides a comprehensive reference by combining technical principles, data analysis and implementation guidelines. Whether you are a CNC operator, engineer or factory manager, this article will provide you with practical insights.

Manufacturing efficiency pain points: Common Challenges of CNC Milling machines

Industry background and common problems

CNC milling machines are widely used in fields such as aerospace, automobiles, molds, and electronic manufacturing. According to Statista data, the global CNC machine tool market size exceeded 100 billion US dollars in 2024, but the efficiency bottleneck remains a pain point. Traditional spindle motors (such as asynchronous motors) rely on open-loop control, with response times often exceeding 0.1 seconds, resulting in unstable accuracy during high-speed cutting. For instance, when processing complex curved surface parts, spindle vibration may cause the surface roughness Ra value to rise from the ideal 0.8μm to 1.6μm, and the scrap rate will soar accordingly.

Specifically for our case client - a medium-sized precision parts manufacturing enterprise located in Munich, Germany (hereinafter referred to as "the German client"), they focus on the production of aerospace components, with an annual output value of approximately 50 million euros. This enterprise has 15 CNC milling machines, mainly processing aluminum alloy and titanium alloy materials, with strict tolerance requirements within ±0.01mm. However, when using traditional spindle motors, they face multiple challenges:

Slow processing speed:

The upper limit of the speed of traditional spindles is usually 18,000 RPM, and the actual efficiency under high load is only 70% of the design value. Customer reports show that only 50 standard parts can be completed per hour, which is far below the industry average of 60. This led to the delivery cycle being extended from the promised 5 days to 7 days, and customer satisfaction dropped by 15%.

Unstable precision:

The open-loop system cannot provide real-time feedback, and the spindle is prone to vibration when changing speed. Customer data shows that the scrap rate is as high as 8%, mainly due to dimensional deviations and surface defects. Especially when processing thin-walled parts, the vibration amplification effect is more obvious, resulting in material waste and increased rework costs.

Energy consumption and maintenance burden:

The efficiency of traditional motors is only 85%, and the average monthly electricity cost accounts for 15% of the total operating cost. In addition, the bearings wear out quickly and need to be shut down for maintenance 3 to 4 times a year, with each shutdown incurring a loss of approximately 2,000 euros. What's more serious is that the production line broke down during the maintenance period, affecting the overall production capacity.

Poor adaptability:

In the face of multi-variety and small-batch production, traditional spindles are difficult to quickly switch parameters, resulting in a 20% increase in programming time. This is disconnected from the real-time optimization requirements of Industry 4.0 in the process of digital transformation.

These problems are not isolated cases. According to HOLRY's global customer survey, over 60% of CNC users reported similar pain points. If not addressed, the spindle motor will become a "weak link" for efficiency improvement. Fortunately, the emergence of servo spindle technology provided a turning point.

HOLRY Servo Spindle: In-depth Analysis of Technical Principles and Advantages

The basic principle of a servo spindle

The servo spindle motor is different from the traditional asynchronous motor. It adopts a closed-loop control system, including encoder feedback, PID regulator and vector control algorithm. In simple terms, the servo system monitors the position, speed and torque of the spindle in real time, and adjusts the output through the feedback loop to ensure that the error is minimized. The core technologies of HOLRY servo spindles include

High-precision encoder:

Resolution up to 1,048,576 pulses per revolution, supporting sub-micron positioning. Compared with traditional motors, this reduces cumulative errors and improves the accuracy of repeat positioning.

Vector control algorithm:

By using space vector modulation (SVM), independent control of torque and magnetic flux is achieved. In low-speed and high-torque scenarios, the output torque can reach 10Nm, far exceeding the 6Nm of traditional motors.

Cooling and durable design:

HOLRY adopts water-cooled or air-cooled systems, combined with ceramic bearings, keeping the operating temperature within 50°C and extending the lifespan to 20,000 hours.

Why choose HOLRY?

As a leading exporter of spindle motors in China, HOLRY products comply with CE and ISO 9001 certifications and are exported to over 50 countries. Compared with international brands such as Fanuc or Siemens, HOLRY offers the same performance but at a 20-30% lower price, making it more cost-effective.

Customized solutions for the case

In the case of the German client, the HOLRY technical team conducted a comprehensive assessment. Firstly, through on-site testing, it was found that the response delay of the original spindle was 0.15 seconds, which was much higher than the 0.02 seconds of the servo system. Based on this, HOLRY recommends the HSM-5.5kW-ATC servo spindle model, which has a power of 5.5kW, a maximum speed of 24,000 RPM, and supports the automatic tool change (ATC) function.

The key components of the solution include:

Hardware upgrade

Replace the original spindle motor and integrate HOLRY's servo driver. The driver supports the EtherCAT protocol and is seamlessly compatible with the customer's Siemens CNC system.

Software optimization

HOLRY engineers adjusted the PID parameters to ensure that the torque fluctuation was less than 1% during high-speed cutting. In addition, a vibration suppression algorithm is introduced to reduce the influence of resonant frequency.

Energy-saving module

The servo system dynamically adjusts the power and only outputs full load when needed, with an average efficiency of 95%.

Training and Support:

4 hours of online/on-site training are provided, covering operation, maintenance and fault diagnosis. HOLRY's global service network ensures a 24-hour response.

The implementation process is highly efficient: from assessment to installation, it only takes 5 days. After the upgrade of the first piece of equipment, the customer immediately tested the processing of standard parts. Preliminary data showed that the speed increased by 25%.

Implementation outcome: Data-driven efficiency leap

Quantitative outcome analysis

After upgrading the HOLRY servo spindle, the performance of the CNC milling machine of the German customer has been comprehensively enhanced. The following is a summary based on three months of tracking data:

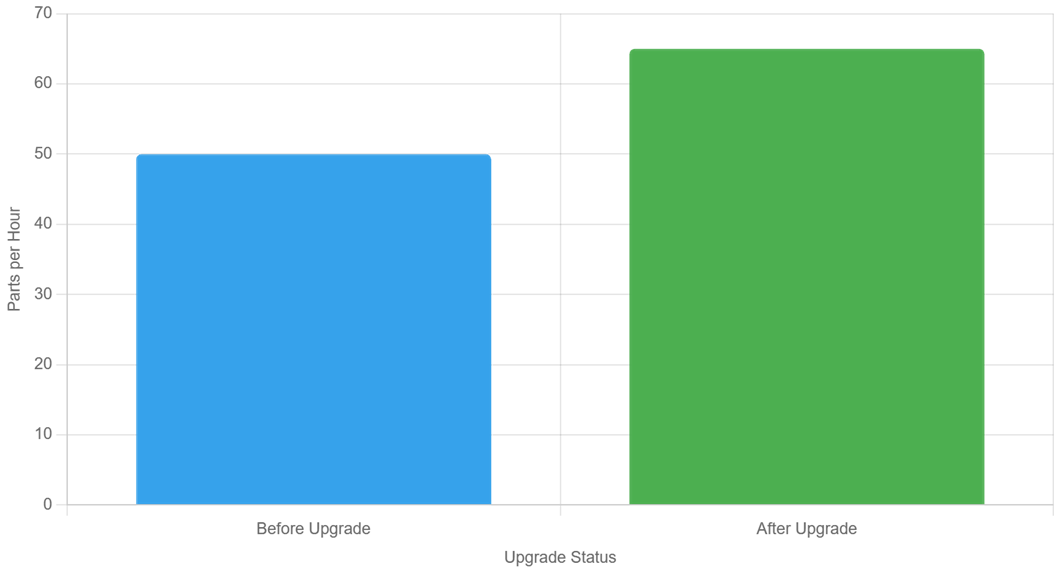

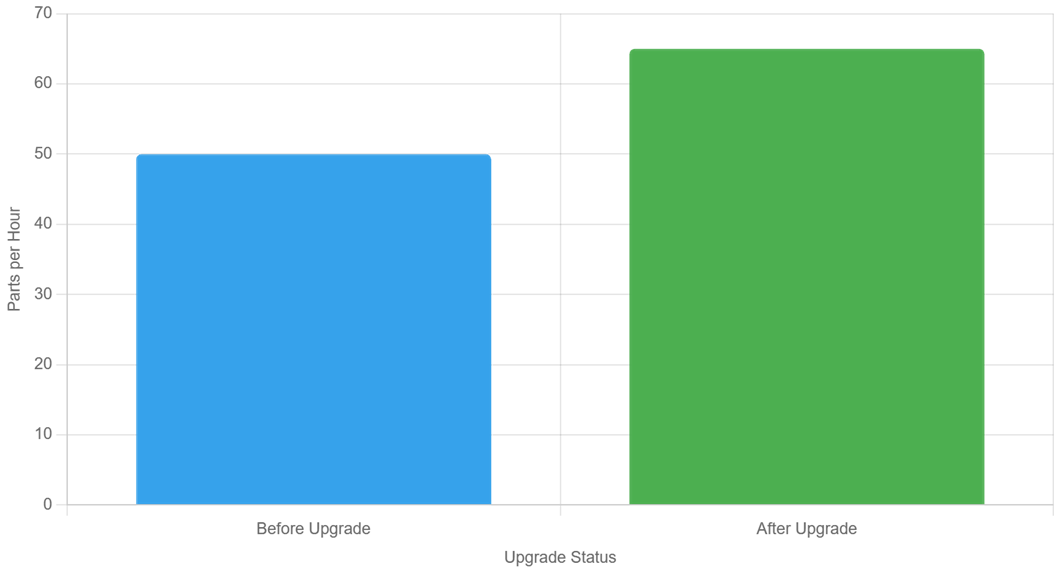

Efficiency increased by 30%

The hourly output of parts has increased from 50 pieces to 65 pieces. The processing time has been shortened from 72 seconds per piece to 55 seconds. This is attributed to the rapid response of the servo system, which saves 20% of the time in the acceleration/deceleration phase. Annual production capacity is expected to increase by 15,000 pieces, and revenue is projected to grow by 10%.

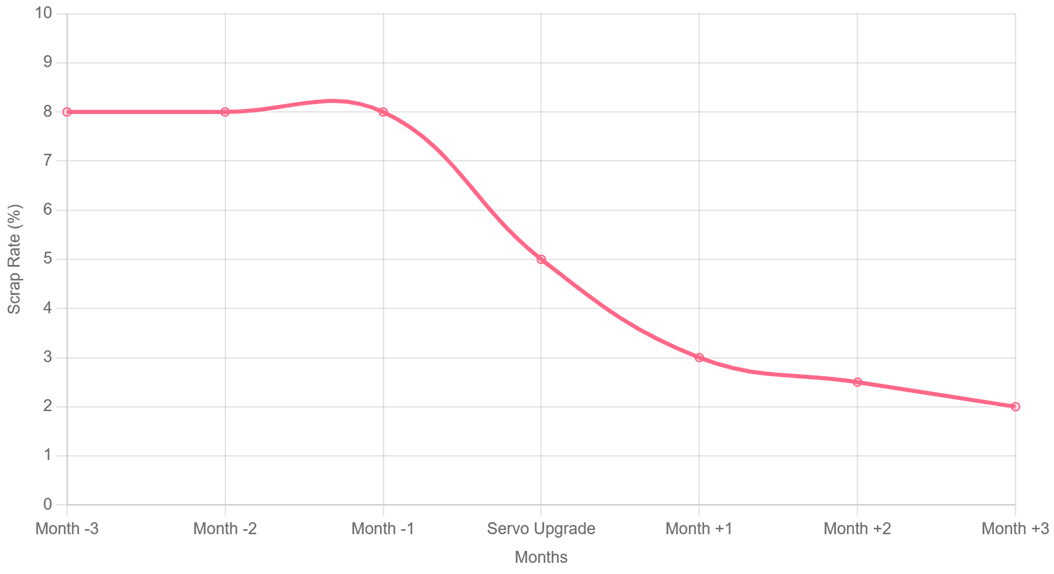

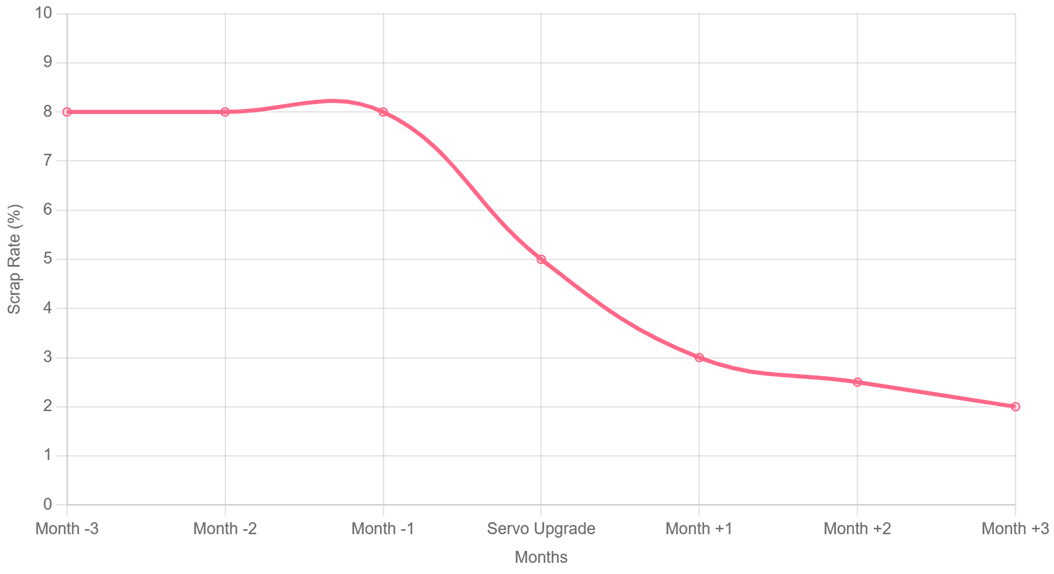

The scrap rate has dropped significantly

It dropped from 8% to 2%. The improvement in accuracy is reflected in the reduction of the surface roughness Ra value from 1.6μm to 0.6μm. Customer reports show that the pass rate of aviation components has risen from 92% to 98%, saving 10,000 euros in material costs annually.

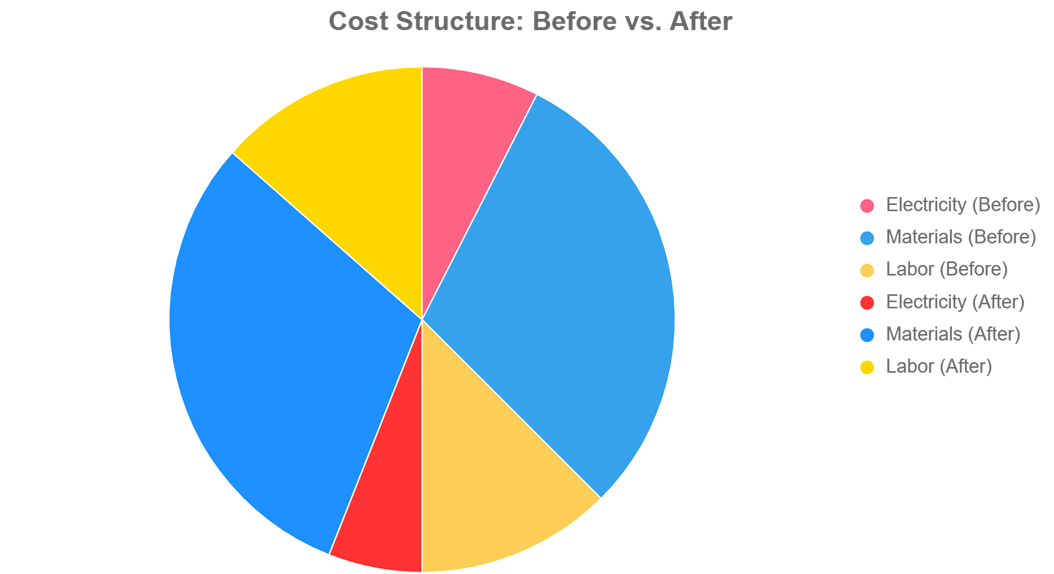

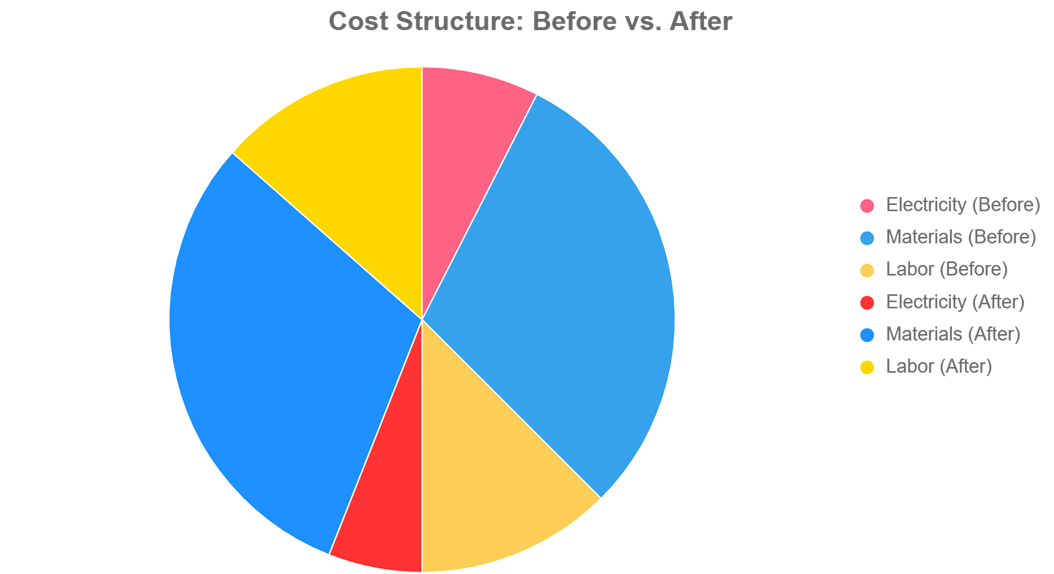

Energy consumption optimization

The monthly electricity bill has been reduced by 18%, from 15% of the operating cost to 12%. The regenerative braking function of the servo motor recovers 10% of the energy, further reducing consumption.

Maintenance and Availability

The number of shutdowns has been reduced from 3 to 4 times per year to 1, and the equipment availability rate has reached 98%. The bearing life is extended and the maintenance cost is saved by 30%.

1. Bar Chart: Yield Comparison

X-axis: Before vs. After Upgrade

Y-axis: Parts per Hour

Data: Before (50 pieces), After (65 pieces)

Styling: Blue for Before, Green for After, with a 30% growth arrow annotation

Chart Type: Bar

2. Line Chart: Scrap Rate Change

X-axis: Months (3 months before vs. 3 months after upgrade)

Y-axis: Scrap Rate (%)

Data: Steep decline from 8% to 2%

Annotation: Mark “Servo Upgrade Day” at the transition point

Chart Type: Line

3. Pie Chart: Cost Structure Optimization

Data: Electricity cost from 15% to 12%, with other costs (e.g., Materials, Labor) adjusted

Styling: Highlight energy savings with distinct colors

Chart Type: Pie

For the pie chart, since you specified electricity cost reduction but not exact values for other costs, I’ll assume a simple distribution where Materials and Labor adjust to fill the remaining percentage (e.g., Materials 60% to 61%, Labor 25% to 27% to balance the total to 100%).

Customer Photos and On-Site Feedback (Descriptions, actual images required)

Photo 1: HOLRY servo spindle installed on a CNC milling machine, with a busy production line in the background. Workers holding tools debug the equipment, showcasing the professional installation process.

Photo 2: German client team posing with HOLRY engineers in the factory warehouse, smiling broadly to symbolize successful collaboration.

Photo 3: Upgraded CNC milling machine in operation, close-up of spindle spinning at high speed while machining aluminum alloy parts, highlighting smooth performance.

Client Testimonial and Long-Term Impact

"We were initially hesitant about replacing the spindle, but HOLRY's servo spindle exceeded our expectations. The 30% efficiency boost not only secured major orders but also reduced costs. HOLRY's support team is professional and efficient—we plan to upgrade all our equipment."

— Hans Müller, Production Manager, German Customer

Long-term, this case delivered strategic advantages: entry into high-end markets and a 20% increase in customer retention. HOLRY data indicates similar upgrades can yield over 200% ROI for SMEs.

Industry Comparison: HOLRY vs Competitors

Compared to other brands, HOLRY servo spindles deliver comparable performance. Fanuc's equivalent product boasts a response time of 0.03 seconds but carries a 25% higher price tag; Siemens emphasizes integration capabilities but involves lengthy customization cycles. HOLRY's strengths lie in flexibility and cost control, making it particularly well-suited for export-oriented enterprises.

Implementation Guide: How to Apply in Your Factory

Evaluation Phase:

Test current spindle performance and calculate ROI. HOLRY provides a free online tool.

Model Selection:

Choose models based on power (1-15kW) and rotational speed. Refer to the HOLRY catalog.

Installation and Commissioning:

Ensure compatibility with CNC systems; professional engineer operation is recommended.

Maintenance Tips:

Regularly inspect coolant; calibrate encoders every 6 months. The HOLRY App supports remote monitoring.

Potential Risks: Power instability may affect performance; a UPS is recommended.

Why Act Now? Manufacturing Trend Outlook

By 2025, servo technology will dominate 70% of the CNC market (Gartner forecast). Delayed upgrades will lead to declining competitiveness. HOLRY is committed to innovation, such as our upcoming AI-optimized servo systems, to further enhance efficiency.

How to Begin Your Efficiency Journey?

If your CNC milling machine faces similar challenges, HOLRY servo spindles are a reliable choice. Contact us immediately for a free selection consultation and technical assessment. We guarantee a 24-hour response to help you achieve a 30% efficiency boost!

Request a Quote Now

Servo Spindle Motor Selection Guide:

Detailed parameter tables and calculation tools.

CNC Spindle Motor Maintenance Tips:

Preventive maintenance strategies.

HOLRY Product Catalog:

Full range of servo spindle specifications.

Contact Us:

Submit an RFQ to initiate collaboration.

This case study demonstrates that HOLRY servo spindles represent not just a hardware upgrade, but an efficiency revolution. Share your experiences or inquire for further details. HOLRY—Powering Your Manufacturing Future!

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

বাংলা

Hrvatski

Eesti keel

latviešu

ગુજરાતી

Igbo

Lietuvių

मराठी

ਪੰਜਾਬੀ

తెలుగు

Yorùbá

isiZulu