How to Choose the Right CNC Spindle for Drilling

Complete Guide for Manufacturers and Engineers

When it comes to precision drilling in CNC operations, one key component can make or break your process—the spindle. The spindle not only determines the drilling performance but also affects the efficiency, durability, and accuracy of the machine. With more than 15 years of manufacturing and export experience, HOLRY CNC Spindle Drilling offers professional-grade solutions to meet the diverse needs of global industries.

In this detailed guide, we will explore everything you need to know about choosing the perfect CNC spindle for drilling, while showcasing why HOLRY CNC Spindle Drilling is a trusted name in the field.

Why the Spindle Matters in CNC Drilling

A CNC spindle is the heart of any drilling system. It holds the cutting tool and rotates it at precise speeds. A high-performance spindle provides:

For industries ranging from aerospace to woodworking, choosing the correct spindle is essential for production efficiency and quality assurance.

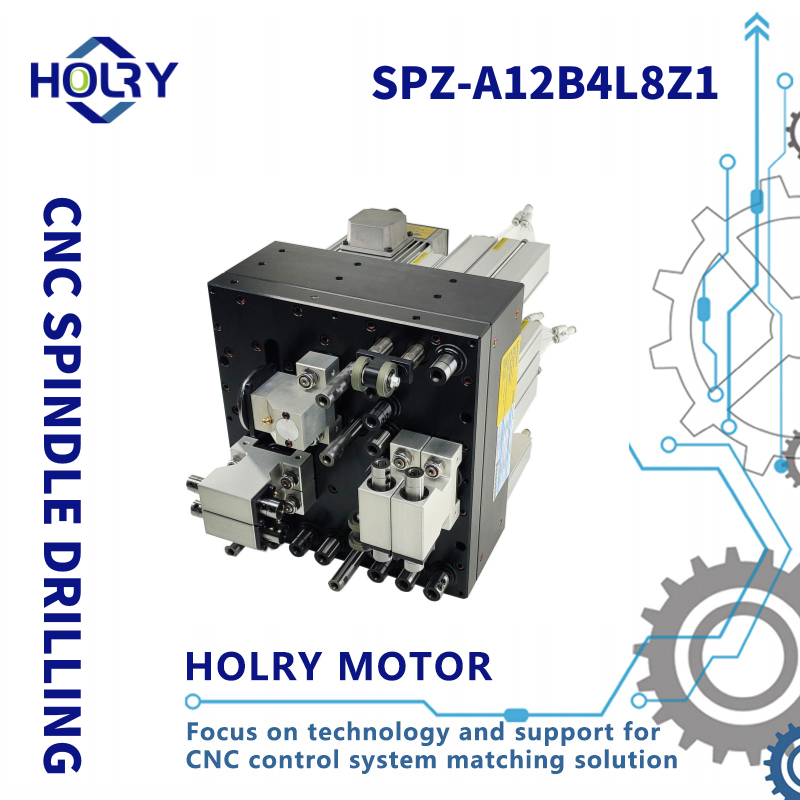

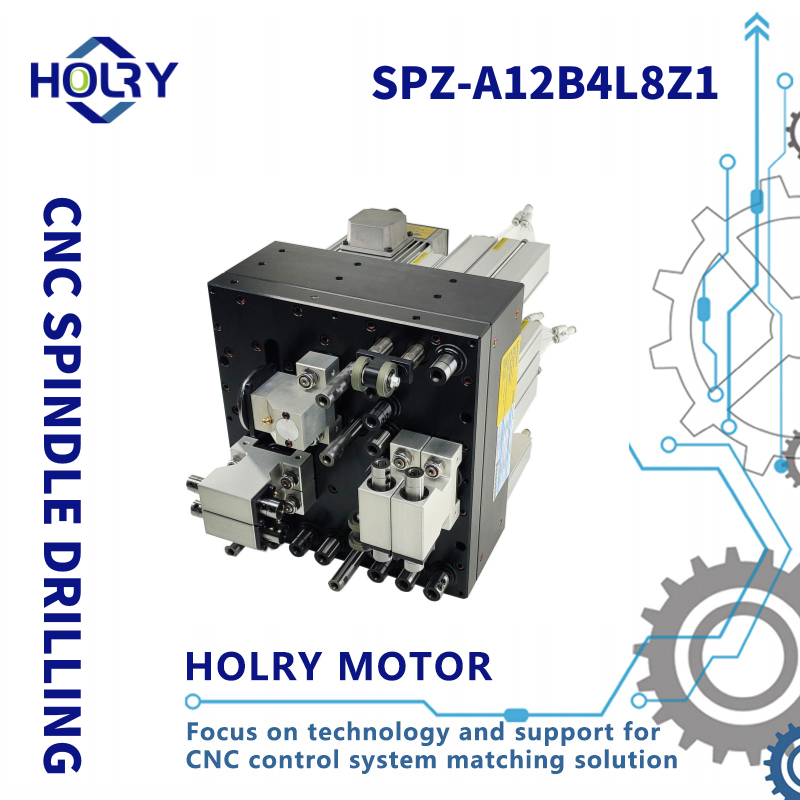

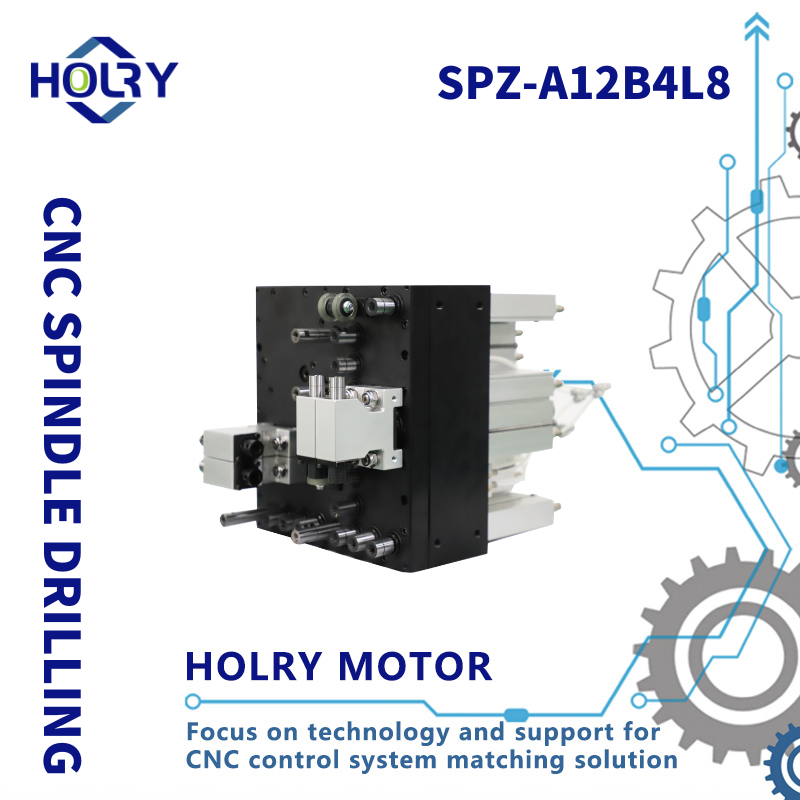

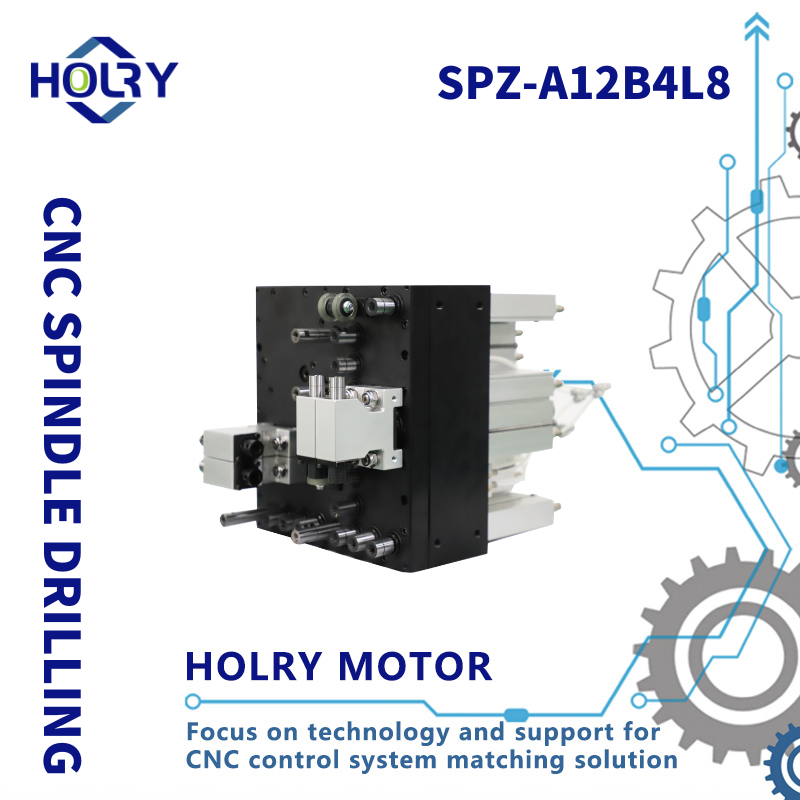

2.2KW Super Charged Vertical Spindle Drilling for CNC Machine

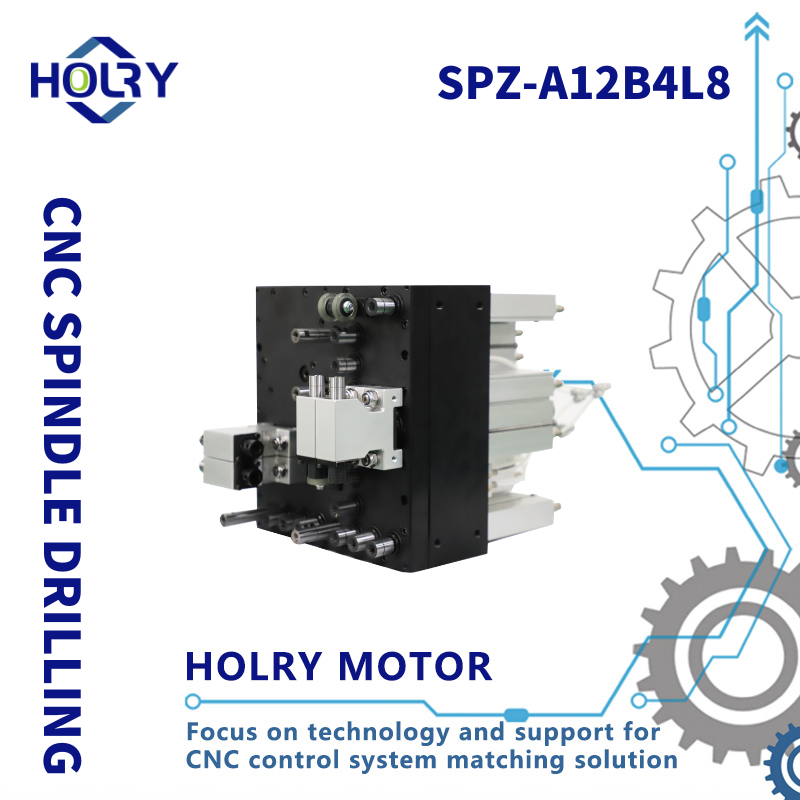

SPZ- A12B4L8

High Quality 2.2KW Super Charged Vertical Spindle Drilling for Woodworking

Types of CNC Drilling Spindles

1. Air-Cooled Spindles

These are ideal for light-duty operations. They use fans to cool down the spindle during operation and are easier to maintain.

Best for: Wood, plastic, and soft materials

2. Water-Cooled Spindles

They offer superior thermal control and are quieter during operation. Water cooling helps maintain stable temperature and high accuracy.

Best for: Continuous operation and precision drilling

3. High-Frequency Spindles

These are compact, lightweight, and offer high-speed rotation up to 60,000 RPM. Ideal for micro-drilling and engraving.

Best for: Electronics, PCB drilling, and fine machining

4. Gear-Driven Spindles

Designed for heavy-duty drilling with higher torque at lower speeds.

Best for: Steel, cast iron, and other metals

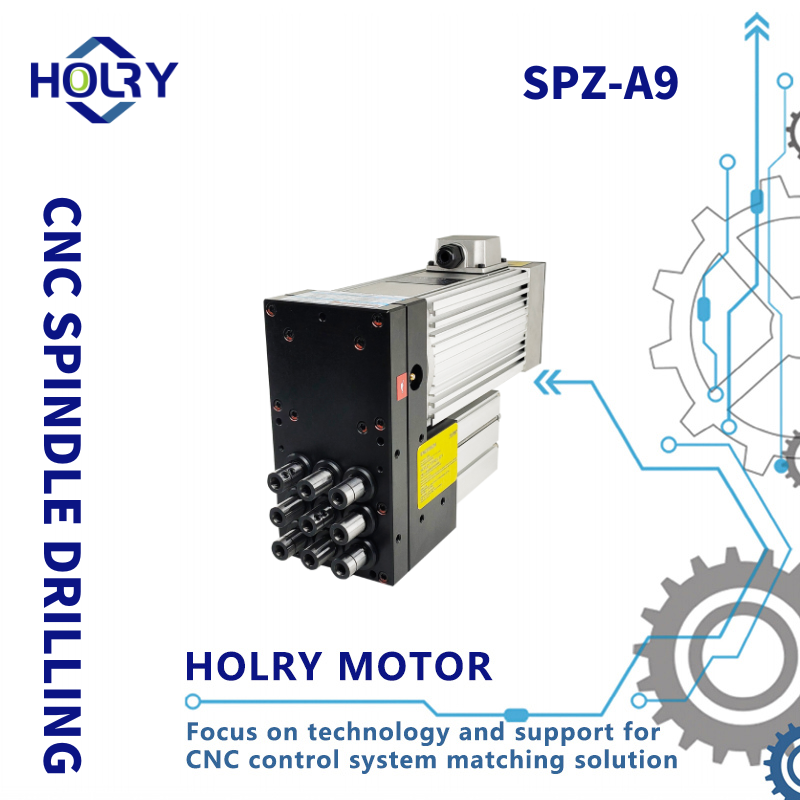

HOLRY CNC Spindle Drilling: Precision Backed by Experience

HOLRY CNC Spindle Drilling has been manufacturing premium spindle systems for 15 years. With a focus on quality, durability, and innovation, HOLRY serves a wide range of industries including:

HOLRY’s spindles are trusted worldwide for their high performance and dependability. Whether you are upgrading your machinery or building a new system, HOLRY offers spindles that deliver stability, efficiency, and precision at scale.

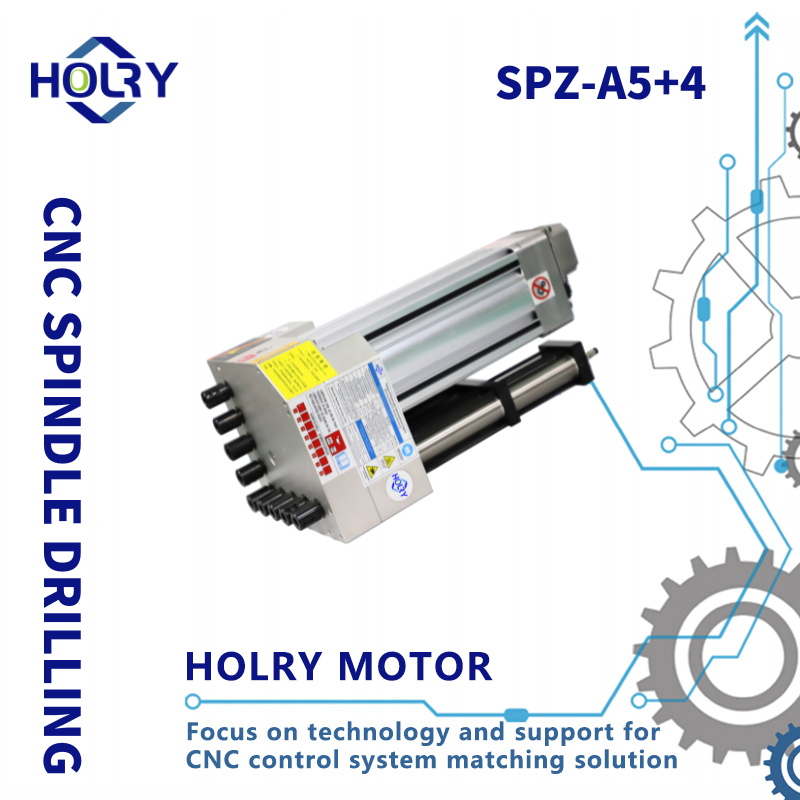

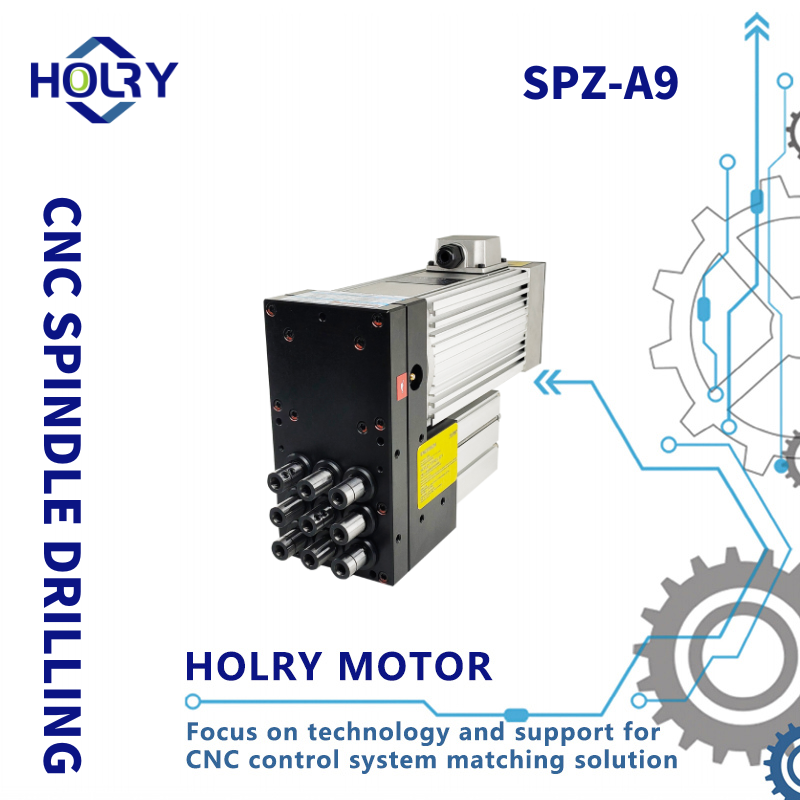

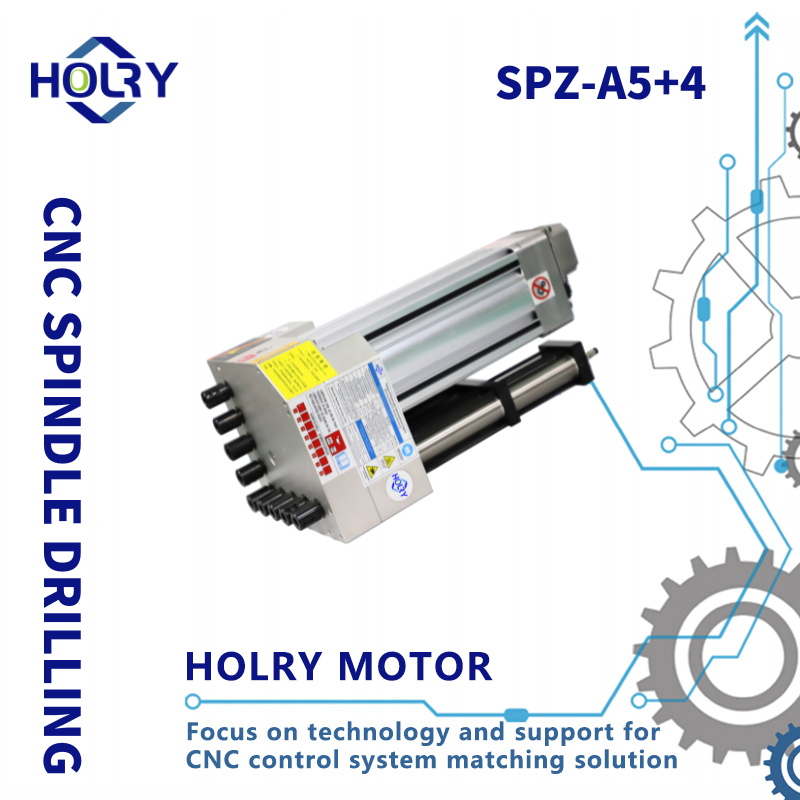

High Quality 2.2KW Air Cooled Super Charged Vertical Spindle Drilling for Woodworking

2.2KW Super Charged Vertical Spindle Drilling for Woodworking

Factors to Consider When Choosing a CNC Drilling Spindle

1. Material Type

Drilling through soft materials like wood or plastic requires a different spindle than cutting hard metals.

Soft Materials: Use high-speed, low-torque spindles

Hard Materials: Use high-torque, low-speed spindles

HOLRY CNC Spindle Drilling provides custom spindle solutions based on the material type and application.

2. RPM and Torque Requirements

High RPM allows faster drilling, especially in softer materials. Torque becomes critical when drilling metals or composites. Look for a spindle that matches your application requirements without sacrificing tool life.

HOLRY's spindle range offers models from 6,000 RPM to 60,000 RPM, covering both high-speed and heavy-duty operations.

3. Tool Holder Type

Common types include ER collet, HSK, and ISO tool holders. They affect rigidity, accuracy, and runout. For tight-tolerance jobs, use precision holders like HSK.

HOLRY supports multiple tool holder types for flexible application needs.

4. Spindle Power

Spindle power ranges from 1kW for light drilling to over 15kW for heavy-duty applications. More power means better performance, but also higher cost and maintenance.

HOLRY’s lineup includes a full spectrum of spindle power options tailored to your production scale.

5. Cooling System

In high-speed or continuous drilling, heat buildup can reduce accuracy. Water-cooled spindles, like those offered by HOLRY, are ideal for maintaining stable temperatures in long production runs.

Top Benefits of HOLRY CNC Spindle Drilling

Over 15 Years of Proven Experience

Trusted by thousands of customers globally with consistent product quality.

Custom Solutions Available

HOLRY can develop custom spindles based on speed, torque, size, and tool interface.

Export-Ready and Certified

HOLRY complies with CE, ISO, and international standards. Spindles are ready for immediate integration.

Wide Product Range

From light-duty engravers to industrial CNC centers, HOLRY offers it all.

Quick Lead Time and Support

With a mature supply chain and dedicated customer service, HOLRY guarantees fast delivery and reliable after-sales support.

Best CNC Spindle Drilling Applications

1. Furniture Manufacturing

HOLRY’s high-speed spindles are ideal for wooden furniture production, allowing smooth drilling without surface damage.

2. PCB and Electronics

For fine holes in circuit boards, HOLRY’s micro-drilling spindles ensure exact tolerances.

3. Metal Fabrication

Gear-driven HOLRY spindles with water cooling can drill tough materials like aluminum and steel effortlessly.

4. Automotive and Aerospace

When accuracy is non-negotiable, HOLRY provides heavy-duty spindles built to maintain consistent quality under intense production conditions.

Spindle Maintenance Tips for Longer Life

Lubricate Bearings Regularly

Keeps the spindle running smooth and noise-free.

Monitor for Vibration

Early vibration detection can prevent costly downtime.

Check Cooling System

Ensure the water or air cooling is functioning properly.

Replace Worn Tools

Dull tools strain the spindle and reduce accuracy.

Customer Testimonials: Why Professionals Trust HOLRY

“We’ve been using HOLRY spindles in our production for over 5 years. Their reliability and performance helped us reduce maintenance costs by 40%.”

— Mark T., CNC Operator, USA

“As a furniture manufacturer, surface quality is key. HOLRY spindles give us the finish we need and the speed our customers demand.”

— Lisa R., Woodworks, Canada

How to Order from HOLRY CNC Spindle Drilling

Ordering is simple and fast. Just visit the official HOLRY website or reach out to their sales team for personalized consultation. They offer:

Technical documentation

Installation support

Worldwide shipping

OEM and custom designs

Conclusion: Choose HOLRY CNC Spindle Drilling for Long-Term Value

Selecting the right spindle for CNC drilling impacts every part of your manufacturing process. From speed and torque to cooling and accuracy, every factor must align with your goals.

HOLRY CNC Spindle Drilling stands out as a leader in spindle technology. With 15 years of experience, world-class quality, and unmatched flexibility, HOLRY delivers solutions that meet the evolving needs of modern manufacturers.

Upgrade your drilling performance today. Trust HOLRY—your reliable partner in CNC spindle technology.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

বাংলা

Hrvatski

Eesti keel

latviešu

ગુજરાતી

Igbo

Lietuvių

मराठी

ਪੰਜਾਬੀ

తెలుగు

Yorùbá

isiZulu