Top 18 Spindle Motor Manufacturers in 2025

Global Leaders Powering the CNC Revolution

As global manufacturing continues to evolve, spindle motors remain the driving force behind high-precision automation. In 2025, the demand for powerful, efficient, and intelligent spindle motor systems is higher than ever. From CNC machining to robotics, the spindle motor is the heart of motion. With advancements in cooling technology, integration with AI, and industry-specific customizations, top spindle motor manufacturers are competing not just in quality but in innovation.

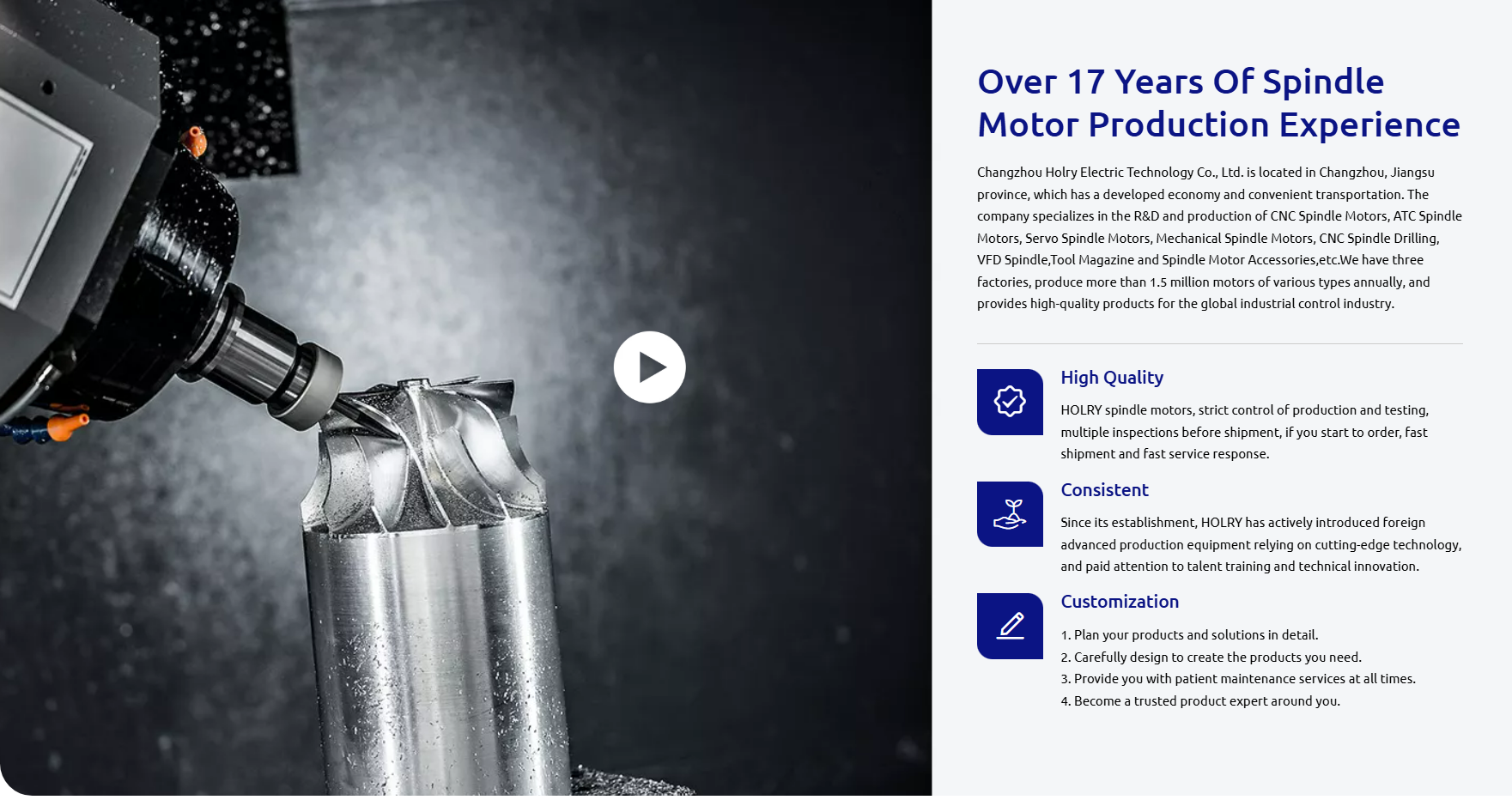

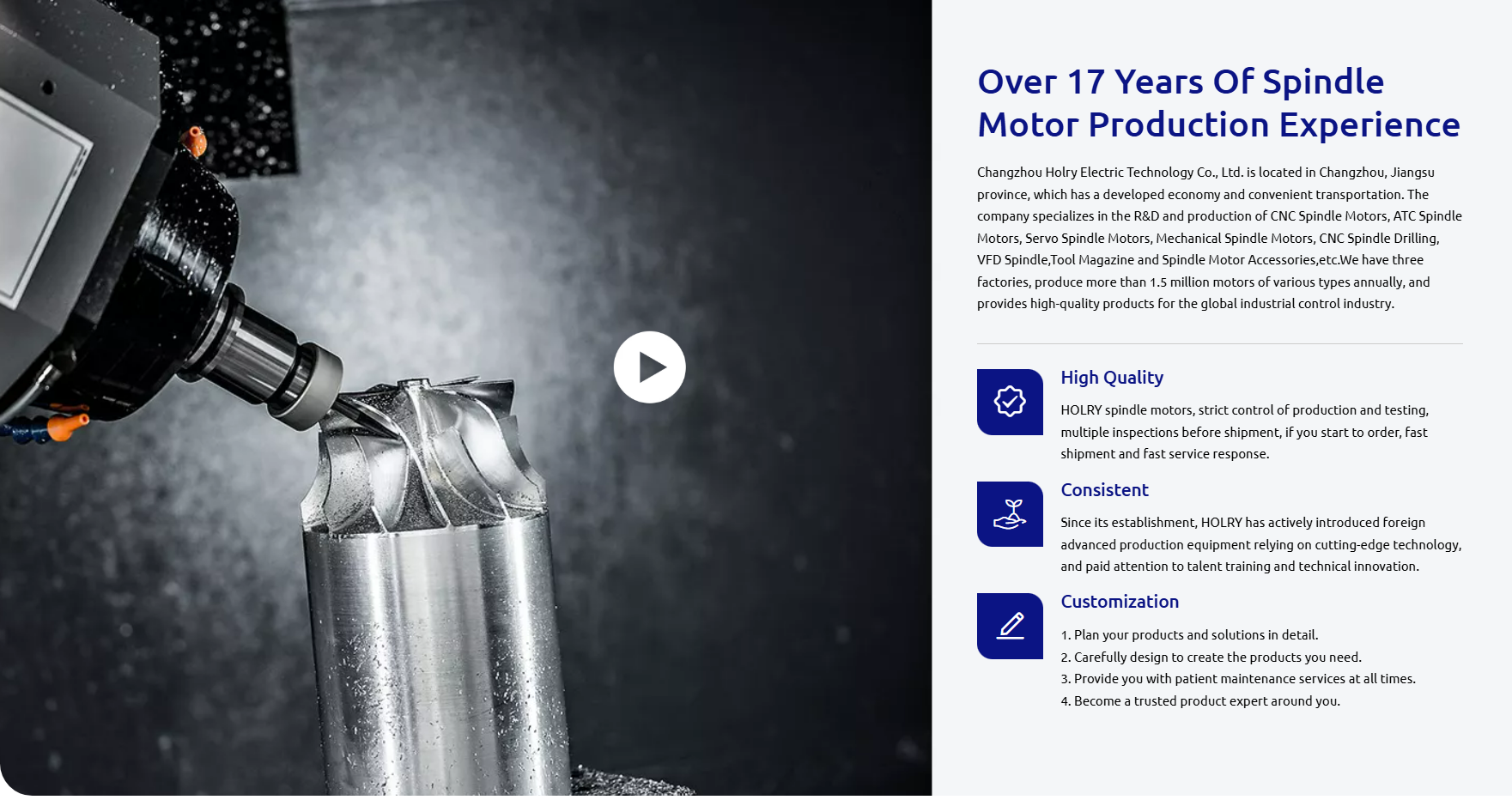

Among these global leaders, HOLRY stands out with 17 years of focused manufacturing and export experience. This blog presents the 18 leading spindle motor manufacturers in 2025, featuring insights on their strengths, markets, and product capabilities.

HOLRY – Precision Spindle Motor Manufacturer from China

With 17 years of experience, HOLRY has established itself as a professional manufacturer of high-performance spindle motors. The company specializes in:

CNC spindle motors

Air-cooled spindle motors

Water-cooled spindle motors

ATC (automatic tool change) spindle motors

Servo spindle motors

Mechanical spindle motors

CNC spindle drilling systems

Spindle motor accessories and drive systems

HOLRY exports to over 80 countries, including the USA, Italy, Germany, Brazil, Russia, and Pakistan. The company’s products are certified with ISO9001, CE, RoHS, and select models with UL certification.

HOLRY also offers OEM and ODM services, catering to specific industry needs. Their motors are widely used in:

With continuous investment in R&D, HOLRY continues to deliver powerful, efficient, and intelligent spindle solutions that exceed customer expectations.

2. Siemens (Germany)

A global leader in automation and drive technology, Siemens offers spindle motors with precision control, integrated safety, and outstanding performance. Their SINAMICS and SIMOTICS spindle series are widely used in CNC and industrial automation.

3. Fanuc (Japan)

Fanuc is synonymous with robotics and CNC systems. Their high-speed spindle motors deliver ultra-reliable performance in automated environments, especially for electronics and automotive industries.

4. Mitsubishi Electric (Japan)

Known for high-quality industrial motors, Mitsubishi offers energy-efficient and high-torque spindle motors for demanding CNC and EDM applications. Their motor series integrate seamlessly with Mitsubishi control systems.

5. Yaskawa (Japan)

Yaskawa focuses on precision and servo spindle motors. Their compact and intelligent spindle designs are perfect for medical, semiconductor, and automation sectors requiring high positioning accuracy.

6. Bosch Rexroth (Germany)

Bosch Rexroth offers intelligent spindle solutions integrated with Industry 4.0 systems. Their high-speed, energy-efficient spindle motors are engineered for durability and digital connectivity.

7. Schneider Electric (France)

Schneider provides customized spindle motor solutions with emphasis on sustainability and smart factory integration. Their spindle systems are found in a variety of mid-sized automation machines.

8. Sanyo Denki (Japan)

Sanyo Denki delivers high-speed micro spindle motors for specialized applications like robotics, 3D printers, and medical equipment. Their cooling and noise control innovations are industry-leading.

9. HSD Mechatronics (Italy)

HSD is a world-renowned spindle motor producer, specializing in woodworking, aluminum, and plastic machining. They offer ATC spindles with high-speed capabilities and exceptional repeatability.

10. Colombo Spindles (Italy)

Giordano Colombo focuses on high-performance electrospindles. Their solutions are used in CNC routers and milling centers for woodworking, composites, and light alloy applications.

11. GMN (Germany)

With a legacy in precision components, GMN manufactures high-speed spindle motors used in grinding, milling, and turning machines. Their designs prioritize rigidity and minimal runout.

12. NSK Nakanishi (Japan)

NSK produces ultra-high-speed electric spindles, ideal for dental, jewelry, and micromachining applications. Known for small form factors and minimal vibration.

13. Parker Hannifin (USA)

Parker's spindle motors offer rugged durability for heavy-duty machining. Their motors integrate with hydraulics, pneumatics, and drives, making them versatile in multi-system environments.

14. Perske (Germany)

Perske specializes in compact spindle motors for routers and cutting systems. Their motors are widely used in sign making, woodworking, and automotive parts manufacturing.

15. Teknomotor (Italy)

Teknomotor is known for developing flexible spindle solutions, including air- and water-cooled models. Their motors serve industries like wood processing, stone carving, and composite cutting.

16. Elte (Italy)

Elte delivers performance spindle motors for manual and automatic tool changes. Their emphasis on precision and custom designs supports niche CNC industries across Europe.

17. IBAG (Switzerland)

IBAG designs ultra-high-speed spindles for fine milling and precision drilling. Their motor technology is ideal for aerospace and mold manufacturing.

18. Delta Electronics (Taiwan)

Delta is emerging as a spindle motor supplier offering compact and affordable solutions for CNC routers and automation equipment. Their smart drives and integration with PLCs make them a flexible choice.

Key Factors When Choosing a Spindle Motor Manufacturer

To select the right spindle motor partner, consider the following:

1. Application Suitability

Different applications require specific torque, speed, and cooling systems. For example, 3D printers need compact and quiet motors, while CNC routers require high-speed ATC models. HOLRY covers this entire spectrum.

2. Certification and Quality

Ensure manufacturers follow international standards. HOLRY meets ISO9001, RoHS, CE, and UL, providing confidence in safety and reliability.

3. Global Support and Delivery

Manufacturers with fast logistics and technical support can prevent production delays. HOLRY serves over 80 countries with reliable lead times.

4. Customization Capabilities

Industries need unique spindle configurations. HOLRY offers OEM and ODM options tailored to your specific engineering and design needs.

Why HOLRY Ranks Among the Best in 2025

17 years of manufacturing excellence

Specialized in diverse spindle technologies

Global reach with exports to 80+ countries

Certified and trusted (ISO, CE, RoHS, UL)

Dedicated R&D for advanced performance

OEM/ODM services to fit unique industrial needs

High reliability across multiple industries

HOLRY stands not just as a supplier, but as a partner in global industrial progress. Whether you're building CNC systems, developing advanced robotics, or producing medical equipment, HOLRY delivers the spindle power that drives performance.

Final Thoughts: The Future of Spindle Motors Starts Now

Spindle motors are evolving alongside smart factories and AI-driven manufacturing. In 2025, performance is no longer just about speed—it’s about integration, precision, and dependability.

From Europe to Asia, from medical labs to aerospace floors, the 18 spindle motor manufacturers listed above are shaping the future. And with its consistent innovation, wide application range, and unmatched export experience, HOLRY is right at the center of that revolution.

Looking for your next reliable spindle motor partner? Choose HOLRY—where power meets precision.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

বাংলা

Hrvatski

Eesti keel

latviešu

ગુજરાતી

Igbo

Lietuvių

मराठी

ਪੰਜਾਬੀ

తెలుగు

Yorùbá

isiZulu